When Dave Freeman was installing our new gas hob during the summer, I asked him about the chimney rising from our Squirrel fire, because the bottom two or three inches were showing signs of corrosion. He said it was a double flue, and that the rusty bit was on the, largely cosmetic, outer tube – would probably respond to a bit of rust treatment and paint. Tonight I ran a finger over the offending part to see how easy it would be to rub down, and my finger went right through it!

So I rang Dave, with two questions in mind. (1) Would it be safe to have a fire tonight? He is, after all, a Boat Safety Scheme inspector. Answer: Best not to. (2) Is it something that would fall within his competence / remit / work schedule to fix? Answer: By all means. In fact, he thinks he should be able to do it towards the end of the coming week, while we are away from the boat. All very satisfactory – apart from the coming bill, of course.

Meanwhile, we'd come back to the marina. Tixall Wide was a treat in the sun this morning, as the traffic got under way.

We sauntered around, waving to the clients of the Canalside café on the way. Everyone is very chilled. In order not to be too chilled tonight, we'll have to use the central heating instead of the fire. But at least the electrons to run it will come from the mains supply, not the batteries. The outside temperature is likely to be pretty low, but the meteorological conditions have produced a fine evening.

Thursday, 19 September 2019

Wednesday, 18 September 2019

3 Day tripper

We came down to Tixall Wide last night.

What with one thing and another, I think this is the first time we've taken Erin Mae out of the marina all year. A succession of medical events, coupled with some family things, meant we needed to be in the south a lot. As for the time we'd allocated to sorting out the kitchen windows, which we'd expected to tackle while cruising a bit (or a lot), it turned out much easier to stay put while I worked on them. That facilitated getting a bit of local help when needed, and picking up what seemed to be regular Amazon deliveries from the Post Office every time I decided another tool was indicated.

In addition, it has to be said, August was not a good month weather-wise. Rain and wind made the maintenance work more difficult, and the problems would have been compounded if we were trying to travel at the same time. But now, with the windows done, and a fine week, we filled the water tank, emptied the other, and have come down to what must be one of the most delightful spots on the network.

Mind you, it's turned cold, so I've laid in some SuperTherm and we'll have a fire tonight. The radiators are good, but nothing quite beats a good Squirrel. Anyway, the Webasto tends to rely a bit too much on the batteries, and even though the clear skies which drop the night-time temperature also mean the solar panel is working well during the day, I like to look after my electrons.

This morning we walked up to the Post Office and then round to Shugborough for coffee and one of their exceedingly good home-made sausage rolls. Back on Erin Mae, it is peaceful and quiet. There are some water birds and butterflies around. We've got to drive home at the end of the week but, for the moment, we're in a very happy space.

What with one thing and another, I think this is the first time we've taken Erin Mae out of the marina all year. A succession of medical events, coupled with some family things, meant we needed to be in the south a lot. As for the time we'd allocated to sorting out the kitchen windows, which we'd expected to tackle while cruising a bit (or a lot), it turned out much easier to stay put while I worked on them. That facilitated getting a bit of local help when needed, and picking up what seemed to be regular Amazon deliveries from the Post Office every time I decided another tool was indicated.

In addition, it has to be said, August was not a good month weather-wise. Rain and wind made the maintenance work more difficult, and the problems would have been compounded if we were trying to travel at the same time. But now, with the windows done, and a fine week, we filled the water tank, emptied the other, and have come down to what must be one of the most delightful spots on the network.

Mind you, it's turned cold, so I've laid in some SuperTherm and we'll have a fire tonight. The radiators are good, but nothing quite beats a good Squirrel. Anyway, the Webasto tends to rely a bit too much on the batteries, and even though the clear skies which drop the night-time temperature also mean the solar panel is working well during the day, I like to look after my electrons.

This morning we walked up to the Post Office and then round to Shugborough for coffee and one of their exceedingly good home-made sausage rolls. Back on Erin Mae, it is peaceful and quiet. There are some water birds and butterflies around. We've got to drive home at the end of the week but, for the moment, we're in a very happy space.

Tuesday, 17 September 2019

Weathertight

Well, the aluminium of the window frame came up trumps.

At both top corners the vertical section coming up to the mitre was bent outwards slightly, but I managed to straighten them with careful use of some screw clamps and a mole wrench, before fixing and sealing the corners with Gorilla epoxy glue. When that was set I applied the neoprene window tape all round the edge and then carefully pressed my long M4 screws through all the holes, piercing the neoprene.

This was my cunning plan for making it easier to locate the screws in their holes. Using long screws as a first step, it was easy to position the window with every screw in a hole. Then, one at at a time, I removed the long screw, squeezed a glob of Sikaflex 221 into the hole and inserted the final fixing screw. I had been concerned about the slight warp in the steel work at the top of the window cut out, but the aluminium of the frame eased itself into shape as the screws were tightened, and it all seems weather-tight.

Overall, I'm really pleased with the techniques I've learned with these windows. Drilling and tapping for an M4 screw now seems pretty ordinary, but I have noted how important it is to have the right tools. My original drill bits and taps were simply not up to the job. Getting pieces of the right quality turned it into something pretty straightforward. Painting has also got better as I've gone along. Thinning the paint appropriately was key to getting as good a finish as I'm going to manage.

A mother brought two of this year's brood for an approving inspection, though they seemed more interested in what was available below the waterline!

At both top corners the vertical section coming up to the mitre was bent outwards slightly, but I managed to straighten them with careful use of some screw clamps and a mole wrench, before fixing and sealing the corners with Gorilla epoxy glue. When that was set I applied the neoprene window tape all round the edge and then carefully pressed my long M4 screws through all the holes, piercing the neoprene.

This was my cunning plan for making it easier to locate the screws in their holes. Using long screws as a first step, it was easy to position the window with every screw in a hole. Then, one at at a time, I removed the long screw, squeezed a glob of Sikaflex 221 into the hole and inserted the final fixing screw. I had been concerned about the slight warp in the steel work at the top of the window cut out, but the aluminium of the frame eased itself into shape as the screws were tightened, and it all seems weather-tight.

Overall, I'm really pleased with the techniques I've learned with these windows. Drilling and tapping for an M4 screw now seems pretty ordinary, but I have noted how important it is to have the right tools. My original drill bits and taps were simply not up to the job. Getting pieces of the right quality turned it into something pretty straightforward. Painting has also got better as I've gone along. Thinning the paint appropriately was key to getting as good a finish as I'm going to manage.

A mother brought two of this year's brood for an approving inspection, though they seemed more interested in what was available below the waterline!

Saturday, 14 September 2019

Wonky!

Doing Erin Mae's second kitchen window, I've come across an unexpected problem.

My very straight edge shows that the steel work in the window area is not completely flat. I don't know how much the window frame will flex – hopefully enough for its neoprene seal to maintain a water-tight join. Meanwhile the painting of the surrounding block has gone well – the weather has been great for it.

Its being nice and shiny is very pleasing – except that it then rather shows up the dullness of the next section!

My very straight edge shows that the steel work in the window area is not completely flat. I don't know how much the window frame will flex – hopefully enough for its neoprene seal to maintain a water-tight join. Meanwhile the painting of the surrounding block has gone well – the weather has been great for it.

Its being nice and shiny is very pleasing – except that it then rather shows up the dullness of the next section!

Wednesday, 4 September 2019

Window done!

Erin Mae's first kitchen window is finally back in place, surrounded by a newly painted panel. The one thing still to do is to fit the black gasket that will cover the screws.

It's been an extraordinarily long process, with the need to solve numbers of problems along the way, and sometimes acquire new tools to do so – appropriate drill bits and taps, for example. The last came today – a countersink bit appropriate for aluminium and small enough to get into the channel where the screws sit. Sometimes I faced a problem with deliveries. For eight years we've had all sorts of things sent to the post office in Great Haywood for us to collect. But of late there's been a problem when a package is being delivered by Hermes – something to do with the shop's insurance. Today's Amazon delivery was to come by Hermes, but I didn't know that until I'd placed the order. So I had to go to the Post Office early and negotiate with them to ensure they would accept it when it came.

The painting has gone really well, though a good finish seems much harder to achieve with this red than it has been with green sections. It's encouraged me to think that I could do the whole side. It would be very obvious it was an amateur job, but at least it would be the same shade all the way down.

I now have to complete the work on the window the other side of the kitchen. That will have its own idiosyncrasies, but at least I've acquired some experience in regard to the principal steps.

It's been an extraordinarily long process, with the need to solve numbers of problems along the way, and sometimes acquire new tools to do so – appropriate drill bits and taps, for example. The last came today – a countersink bit appropriate for aluminium and small enough to get into the channel where the screws sit. Sometimes I faced a problem with deliveries. For eight years we've had all sorts of things sent to the post office in Great Haywood for us to collect. But of late there's been a problem when a package is being delivered by Hermes – something to do with the shop's insurance. Today's Amazon delivery was to come by Hermes, but I didn't know that until I'd placed the order. So I had to go to the Post Office early and negotiate with them to ensure they would accept it when it came.

The painting has gone really well, though a good finish seems much harder to achieve with this red than it has been with green sections. It's encouraged me to think that I could do the whole side. It would be very obvious it was an amateur job, but at least it would be the same shade all the way down.

I now have to complete the work on the window the other side of the kitchen. That will have its own idiosyncrasies, but at least I've acquired some experience in regard to the principal steps.

Sunday, 25 August 2019

Kitchen window phases 5a – 5n

The last ten days have seen the window work on Erin Mae proceeding steadily. The most satisfactory part was successfully drilling and tapping the hull with some extra holes to take machine screws that will fix the frame in place.

I've cleaned out plenty of threads before, but these were the first I'd cut myself. Having the right equipment was key – a 3.3mm cobalt steel drill bit, some cutting paste and an M4 tap that was tough enough for the job. In retrospect, I wonder what it was I was worried about. Now the positions of the holes in the frame and those in the hull match each other and I've started on the painting.

The heatwave meant I didn't try to do too much today. I had a BBQ to cook.

I've cleaned out plenty of threads before, but these were the first I'd cut myself. Having the right equipment was key – a 3.3mm cobalt steel drill bit, some cutting paste and an M4 tap that was tough enough for the job. In retrospect, I wonder what it was I was worried about. Now the positions of the holes in the frame and those in the hull match each other and I've started on the painting.

The heatwave meant I didn't try to do too much today. I had a BBQ to cook.

My best beloved took the photos so doesn't appear in shot. She looked after the salad and the strawberries. And very nice it was too!

Thursday, 15 August 2019

Kitchen window phase 4

Epoxy puttying was duly completed today. No pictures of the job, basically because it looked very uninteresting, and anyway, how many photos of yours truly working on the kitchen window can you stand? The putty worked pretty well – getting my hands thoroughly wet before handling it helped.

The photo is from the Amazon page. I had some epoxy putty – Milliput – some years ago that came as two separate blocks, so it's intriguing to have it all in one roll. I'm not sure what technique they use for preventing it going off at the interface between the two parts. Perhaps there is some sort of barrier. Cutting off a slice was easy, but gave me a lot of wastage, given the size of the hole I was filling. I am also hoping that it won't have damaged whatever barrier they do have in place.

Rain again tomorrow – possibly yet another day of feet up, book out.

Tuesday, 13 August 2019

Kitchen window phase 3 – Dremelising

We spent longer in the south than intended, because the appalling weather was going to make window work difficult, and we didn't fancy just sitting inside Erin Mae in the marina while the storms roared outside. Today, however, work resumed.

The new Dremel immediately proved its worth. My first task is to fill a hole where some engineer or other had drilled and tapped too close to the edge of the steel. I have some epoxy putty for that but, as my friend Brian would say, preparation is everything. I attached a small wire wheel to the Dremel - one of about 60 items in a £10 variety pack from Amazon, and it powered through rusty bits and old silicone. I've applied some Fertan and should be able to do the puttying tomorrow.

I can't see any sign of how the wood inner window frame was held in place (apart from the method thoroughly dissed in a previous post!). So today I have also drilled and countersunk four 3.5 mm holes through the hull, and used stainless steel screws to hold the frame tight. I was very glad to have brought my old mains drill – it made a much quicker job of penetrating the hull and cutting the countersinks than my 18v cordless.

At last I feel I'm making some progress. I suspect tomorrow's weather will put a halt to it for 24 hours.

The new Dremel immediately proved its worth. My first task is to fill a hole where some engineer or other had drilled and tapped too close to the edge of the steel. I have some epoxy putty for that but, as my friend Brian would say, preparation is everything. I attached a small wire wheel to the Dremel - one of about 60 items in a £10 variety pack from Amazon, and it powered through rusty bits and old silicone. I've applied some Fertan and should be able to do the puttying tomorrow.

I can't see any sign of how the wood inner window frame was held in place (apart from the method thoroughly dissed in a previous post!). So today I have also drilled and countersunk four 3.5 mm holes through the hull, and used stainless steel screws to hold the frame tight. I was very glad to have brought my old mains drill – it made a much quicker job of penetrating the hull and cutting the countersinks than my 18v cordless.

At last I feel I'm making some progress. I suspect tomorrow's weather will put a halt to it for 24 hours.

Tuesday, 30 July 2019

Dremel

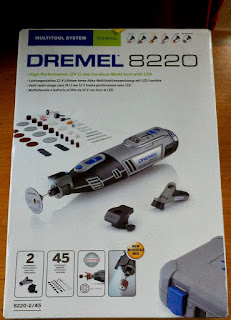

I've wanted a Dremel for ages – along with electronic things it's the sort of gadget that raises my adrenaline levels – but the reading on the "need" scale never quite hit the justification mark. Until yesterday, when, observing Dave apply his angle grinder to the not-so-subtle art of cutting off a couple of rusted screw heads, I realised that a cutter with a much smaller diameter would do far less damage to the surrounding aluminium of Erin Mae's window frame.

After that, it wasn't hard to think up all sorts of extra uses for a Dremel. And once I'd done my research on the relevant websites, I was done for. I waited half an hour to allow hormones to subside, in order to conduct a reality check (well, it was a whole weekend when I bought my guitar) and ordered it.

It will be a while before it gets used in earnest, not least because we drove south today in the torrential rain because of some important medical appointments over the next week. I wonder if I can think of something interesting to do with it while we're here…

Monday, 29 July 2019

Kitchen window phase 2

Not much work on the window over the last two days – it was far too wet in the West Midlands. But today Dave Freeman combined a visit to make an adjustment on the new gas hob with helping me get out the final two screws holding in Erin Mae's kitchen window.

In the event it needed his angle grinder to cut the heads. Fortunately the scratches it left on the frame will eventually be covered up by the neoprene insert. At least we managed to remove the window.

After Dave had left I went round all the screw holes in the hull with an M4 tap to clean out the threads.

It was a satisfying job, but I'm still amazed that whoever last put the window in didn't attach it via these threads, but via wood screws going all the way through them and into the interior wooden frame. Two of those are actually still in place, with their heads missing. The up side to that is that they are holding the wooden frame in position while I work on the whole thing.

Now I have to plan the next steps. Some of the holes in the aluminium frame seem a little large and I'm concerned that the heads of the new screws will pass through under pressure. I also want to enlarge one or two holes anyway so that the screws don't have to be forced in at an angle. What I'll have to do is slowly becoming clearer in my mind. For the moment I've re-fitted the window since we have rain tomorrow and then a long weekend in the south to attend to some medical matters. The window, of course, is now even less waterproof than it was, so I'll leave it covered with a cheap tarpaulin while we're away.

In the event it needed his angle grinder to cut the heads. Fortunately the scratches it left on the frame will eventually be covered up by the neoprene insert. At least we managed to remove the window.

After Dave had left I went round all the screw holes in the hull with an M4 tap to clean out the threads.

It was a satisfying job, but I'm still amazed that whoever last put the window in didn't attach it via these threads, but via wood screws going all the way through them and into the interior wooden frame. Two of those are actually still in place, with their heads missing. The up side to that is that they are holding the wooden frame in position while I work on the whole thing.

Now I have to plan the next steps. Some of the holes in the aluminium frame seem a little large and I'm concerned that the heads of the new screws will pass through under pressure. I also want to enlarge one or two holes anyway so that the screws don't have to be forced in at an angle. What I'll have to do is slowly becoming clearer in my mind. For the moment I've re-fitted the window since we have rain tomorrow and then a long weekend in the south to attend to some medical matters. The window, of course, is now even less waterproof than it was, so I'll leave it covered with a cheap tarpaulin while we're away.

Friday, 26 July 2019

Kitchen window phase 1

The indications of damage from water ingress around Erin Mae's left-hand kitchen window have been getting worse, and they have to be addressed.

One of the targets for this period was to remove the window and sort it all out. Last year's experience with a living area window gave me confidence for everything that has to be done once the hole is window-less, but I am still a bit nervous about bodywork. In particular, given the history with Erin Mae's windows, that I discovered well after we bought her, I expect to face problems resulting from the technique of those who first endeavoured to make her water-tight.

The proper method for attaching a window is to use machine screws through its aluminium frame, secured into tapped holes in the hull. The internal wooden frame (see the picture) is secured by countersunk screws from the the outside, which pass through the hull and into the wood, and whose heads are covered by the aluminium frame itself. But whoever effected the repair when the windows first gave problems chose to fix the aluminium frame with wood screws passing through the hull and into the internal wooden frame, trusting that the grip between them would be enough to prevent ingress. It never has been – I imagine that just the natural movement of the wood and the metal expanding in hot weather would be enough to cause a failure. So today, with some trepidation, I started on removing the window.

It was as I had feared – most of the screws were wood screws passing through the hull into the internal wooden frame. I tapped my screwdriver with a hammer to loosen them, and most came out fine. But on two the head had rusted too much to get a grip – I don't understand why they didn't use stainless steel screws. I tried to remove them with a screw extractor kit (thanks, Ted!) but they were too hard for that to make any impression.

So I phoned Dave Freeman, the engineer who fitted our new gas hob on Monday, and he's going to drop by shortly to see what he can do to get the screws out for me. Unfortunately, I can't yet see whether my eventual solution will necessitate drilling any more holes in the hull – the two stuck screws are in just the wrong position for me to move the frame sufficiently to have a look.

Debit it to experience, Uncle Paul would have said.

One of the targets for this period was to remove the window and sort it all out. Last year's experience with a living area window gave me confidence for everything that has to be done once the hole is window-less, but I am still a bit nervous about bodywork. In particular, given the history with Erin Mae's windows, that I discovered well after we bought her, I expect to face problems resulting from the technique of those who first endeavoured to make her water-tight.

The proper method for attaching a window is to use machine screws through its aluminium frame, secured into tapped holes in the hull. The internal wooden frame (see the picture) is secured by countersunk screws from the the outside, which pass through the hull and into the wood, and whose heads are covered by the aluminium frame itself. But whoever effected the repair when the windows first gave problems chose to fix the aluminium frame with wood screws passing through the hull and into the internal wooden frame, trusting that the grip between them would be enough to prevent ingress. It never has been – I imagine that just the natural movement of the wood and the metal expanding in hot weather would be enough to cause a failure. So today, with some trepidation, I started on removing the window.

It was as I had feared – most of the screws were wood screws passing through the hull into the internal wooden frame. I tapped my screwdriver with a hammer to loosen them, and most came out fine. But on two the head had rusted too much to get a grip – I don't understand why they didn't use stainless steel screws. I tried to remove them with a screw extractor kit (thanks, Ted!) but they were too hard for that to make any impression.

So I phoned Dave Freeman, the engineer who fitted our new gas hob on Monday, and he's going to drop by shortly to see what he can do to get the screws out for me. Unfortunately, I can't yet see whether my eventual solution will necessitate drilling any more holes in the hull – the two stuck screws are in just the wrong position for me to move the frame sufficiently to have a look.

Debit it to experience, Uncle Paul would have said.

Wednesday, 24 July 2019

Hot

We'd intended to go to Stafford to get our bikes looked at today and had thought about visiting Stafford castle. In the event it was far too hot to be faffing around in the open with the bike carrier. We woke up late after the excitement of the night's thunderstorms and the main thing after breakfast was to take Erin Mae across to the service wharf for a pump-out – some things you can't simply ignore. But then it was back to our own jetty to consider how best to spend the day over a coffee. Other life-forms were also pretty stationary.

In the end, we didn't do a lot. Once the fiercest heat had gone I took the pram hood cover off and washed away the spiders and their residue – they get absolutely everywhere. No need to say, it all dried in a jiffy.

It seems it's going to be even hotter tomorrow.

In the end, we didn't do a lot. Once the fiercest heat had gone I took the pram hood cover off and washed away the spiders and their residue – they get absolutely everywhere. No need to say, it all dried in a jiffy.

It seems it's going to be even hotter tomorrow.

Tuesday, 23 July 2019

Oakamoor

I'd earmarked today as the best day for a bike ride – it was due to be warm and dry (and was). We put the bikes on the carrier and drove up through Uttoxeter to Denstone Hall farm shop and café. As these establishments go it was pretty impressive. The environment was open, busy and friendly and the coffee wasn't bad. I liked the lampshades over the counter.

Then we walked with our bikes across the road, through the churchyard and dropped down onto the Oakamoor – Denstone Greenway. From there it would be just under 5 miles to Oakamoor, along the path of an old railway track.

It was very pleasant, with just one station on the way that had been converted into someone's house. The map indicates that it follows the Churnet Valley as it curves round the edge of the Alton Towers estate, but we didn't see much of the river until we reached our destination. In Oakamoor there's a notable bridge over the river…

and a large recreational area with a car park and picnic tables.

All in all, a good place to have lunch!

From there on, it was all downhill – and I don't mean in terms of ease of cycling. As we started back along the track I noticed that my front tyre had split, and a few seconds later, so had the inner. My puncture repair kit had only patches, and nothing for an outer tyre. I didn't think Elastoplast from the first aid kit would do the trick. After considering our options, my best beloved walked my bike back to the picnic carpark, while I cycled hers 5 miles back to the café where we had started. Since I didn't want to change her bike's geometry it was an uncomfortable and energetic ride with my knees up around my ears. But no doubt it was very good for the muscles. I put her bike on the carrier, set the satnav for Oakamoor and found myself on an extraordinary journey through the Staffordshire ups and down which included passing through Alton village and a rather nervy trip down a very long, windy and steep single track road to Oakamoor village.

Tomorrow a trip to Halfords in Stafford beckons, to see what can be done about my own bike's tendency to acquire punctures when we are out in the countryside together.

Then we walked with our bikes across the road, through the churchyard and dropped down onto the Oakamoor – Denstone Greenway. From there it would be just under 5 miles to Oakamoor, along the path of an old railway track.

It was very pleasant, with just one station on the way that had been converted into someone's house. The map indicates that it follows the Churnet Valley as it curves round the edge of the Alton Towers estate, but we didn't see much of the river until we reached our destination. In Oakamoor there's a notable bridge over the river…

and a large recreational area with a car park and picnic tables.

All in all, a good place to have lunch!

From there on, it was all downhill – and I don't mean in terms of ease of cycling. As we started back along the track I noticed that my front tyre had split, and a few seconds later, so had the inner. My puncture repair kit had only patches, and nothing for an outer tyre. I didn't think Elastoplast from the first aid kit would do the trick. After considering our options, my best beloved walked my bike back to the picnic carpark, while I cycled hers 5 miles back to the café where we had started. Since I didn't want to change her bike's geometry it was an uncomfortable and energetic ride with my knees up around my ears. But no doubt it was very good for the muscles. I put her bike on the carrier, set the satnav for Oakamoor and found myself on an extraordinary journey through the Staffordshire ups and down which included passing through Alton village and a rather nervy trip down a very long, windy and steep single track road to Oakamoor village.

Tomorrow a trip to Halfords in Stafford beckons, to see what can be done about my own bike's tendency to acquire punctures when we are out in the countryside together.

Monday, 22 July 2019

Hob

When Dave Freeman did our boat safety certificate examination at the end of last year, he noted that one of the burners on the gas hob was leaking very slightly – not enough to fail it, but an advisory that we should probably do something about it. I asked about repair, and he responded that it would probably be cheaper to buy a new hob. I asked who he would recommend to fit it when I'd bought it, and he said "Me!" So over the winter I researched hobs and found that the obvious replacement would be exactly the same model from New World, who were extremely helpful on the phone. Doing it that way worked out cheaper than getting something via Amazon. Today Dave came to fit it.

Getting the old one out was easy enough. But putting the new one in place was not. It transpired that even though it had the same part number as the old there were some significant differences – not really surprising after twelve years. The main problem was that the protective cover underneath was considerably larger, and wouldn't fit into the hole in the work surface.

In the end we removed both covers and put the old one on the new hob. It needed some bending and an extra hole for one of the screws needed to keep it in place, and was a very tight fit, but Dave finally managed to get it firmly in position.

At that point he decided he certainly wasn't going to take it out again to attach the gas and electricity supplies – it was fitting snugly and needed to be left alone. So the supplies had to be worked on from underneath. Out came the oven and grill!

When everything was connected and ready for testing, he found that the push button ignition switch had previously been supported underneath by the protective cover – which we had removed. The cover from the old hob wasn't big enough and the whole switch was dropping through its hole when pressed. It had a thread but no nut to keep it in place. Fortunately the switch on the old hob did have a nut on its thread, of the right size to fit the new one.

So now Erin Mae has a working, safe hob – and we're ready for tea!

Getting the old one out was easy enough. But putting the new one in place was not. It transpired that even though it had the same part number as the old there were some significant differences – not really surprising after twelve years. The main problem was that the protective cover underneath was considerably larger, and wouldn't fit into the hole in the work surface.

In the end we removed both covers and put the old one on the new hob. It needed some bending and an extra hole for one of the screws needed to keep it in place, and was a very tight fit, but Dave finally managed to get it firmly in position.

At that point he decided he certainly wasn't going to take it out again to attach the gas and electricity supplies – it was fitting snugly and needed to be left alone. So the supplies had to be worked on from underneath. Out came the oven and grill!

When everything was connected and ready for testing, he found that the push button ignition switch had previously been supported underneath by the protective cover – which we had removed. The cover from the old hob wasn't big enough and the whole switch was dropping through its hole when pressed. It had a thread but no nut to keep it in place. Fortunately the switch on the old hob did have a nut on its thread, of the right size to fit the new one.

So now Erin Mae has a working, safe hob – and we're ready for tea!

Sunday, 21 July 2019

Cafés

The café beside Haywood Lock was always a bit quirky, but there would sometimes be a nice open fire when it was cold, a crowd of coffee-drinking gongoozlers on the outside tables when it was hot, and Sunday lunch done in two formal sittings. But for the last few months…

it has been closed, and shows every sign of being converted into residences. Just up the towpath Great Haywood junction, of course, is the Canalside Farm Shop and café, where we went for lunch today.

I know – should have taken the photo before we started eating! My best beloved had a beetroot wrap (!) with chicken goujons, chips and bits and pieces on the side, and the chips were large, well cooked and crunchy – just what chips should be . I had one of their double Staffordshire oatcakes with four different fillings and a salad on the side – it's one of their more unusual and satisfying dishes.

Farm, shop and café all seem to be doing really well, which we're glad about, but you wonder whether it's this competition that has led to the closure of the lock café. Perhaps they're just doing a total re-furbishment and will re-open as an eatery in time.

it has been closed, and shows every sign of being converted into residences. Just up the towpath Great Haywood junction, of course, is the Canalside Farm Shop and café, where we went for lunch today.

I know – should have taken the photo before we started eating! My best beloved had a beetroot wrap (!) with chicken goujons, chips and bits and pieces on the side, and the chips were large, well cooked and crunchy – just what chips should be . I had one of their double Staffordshire oatcakes with four different fillings and a salad on the side – it's one of their more unusual and satisfying dishes.

Farm, shop and café all seem to be doing really well, which we're glad about, but you wonder whether it's this competition that has led to the closure of the lock café. Perhaps they're just doing a total re-furbishment and will re-open as an eatery in time.

Wednesday, 17 July 2019

Flow

At long last we've come up to Erin Mae for more than just a night. Earlier in the year we paid a couple of visits. The first was to get the systems back on after the winter, and the second was to relieve my nervousness about one or two things after a sizeable time away. But various events and obligations conspired to keep us in the south for an extra two months, so it's good to have been able finally to travel up yesterday with what's required for a longer stay – though we can't yet push off on an extended trip.

I've installed a new type of water filter cartridge under the sink, and have been astonished by how fast the water is running through it. Mind you, I'm very suspicious. The last time I got anything more than just a trickle from the tap's cold water position we found, at the end of the season, that it was because the cartridge hadn't been seated properly, and was letting water flow round it instead of through it. Somehow we'd survived a summer of drinking unfiltered water with no ill effects. So I've re-inserted the current one, trying to be very careful about its position – but it's actually very difficult to be sure, as you screw the holder into place, that the cartridge inside is exactly where it should be. Ah well, let's hope it's the drinking water that runs, and not our insides!

Less rapid has been the flow down the plughole in the bathroom basin. The drain pipe has an uncomplicated path to the outside, and we're pretty careful about what goes down it, so I've not a clue what was causing the blockage – and I don't really want to think about it! Filling the basin and using a towel to pump things out had no effect, so finally today I took a plunger to it, and that did the job. Normal flow restored!

Here's to everything else flowing in a reasonably smooth fashion over the next few months.

I've installed a new type of water filter cartridge under the sink, and have been astonished by how fast the water is running through it. Mind you, I'm very suspicious. The last time I got anything more than just a trickle from the tap's cold water position we found, at the end of the season, that it was because the cartridge hadn't been seated properly, and was letting water flow round it instead of through it. Somehow we'd survived a summer of drinking unfiltered water with no ill effects. So I've re-inserted the current one, trying to be very careful about its position – but it's actually very difficult to be sure, as you screw the holder into place, that the cartridge inside is exactly where it should be. Ah well, let's hope it's the drinking water that runs, and not our insides!

Less rapid has been the flow down the plughole in the bathroom basin. The drain pipe has an uncomplicated path to the outside, and we're pretty careful about what goes down it, so I've not a clue what was causing the blockage – and I don't really want to think about it! Filling the basin and using a towel to pump things out had no effect, so finally today I took a plunger to it, and that did the job. Normal flow restored!

Here's to everything else flowing in a reasonably smooth fashion over the next few months.

Subscribe to:

Posts (Atom)